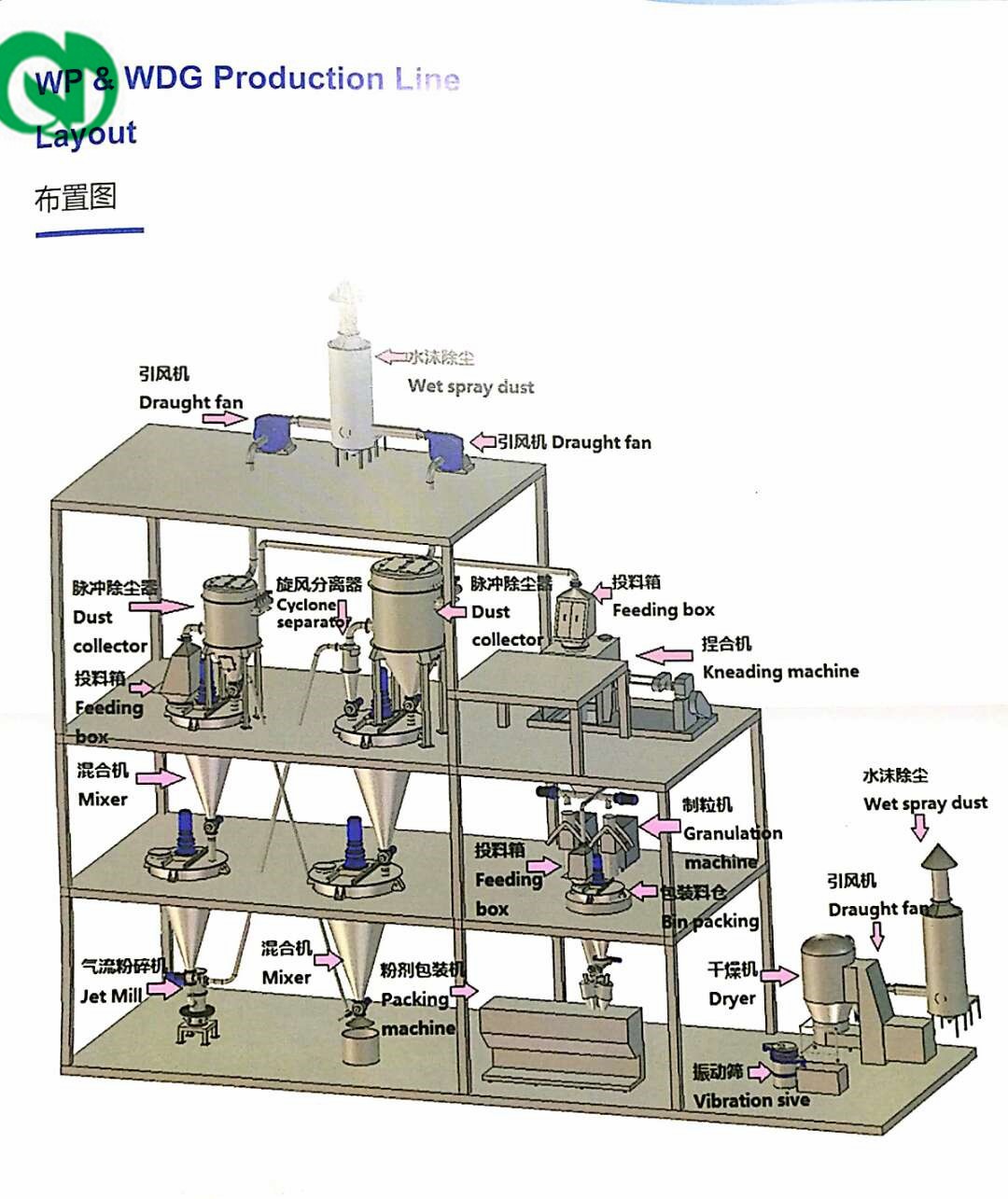

WP-WDG System-Nyorera kune Agrochemical Munda

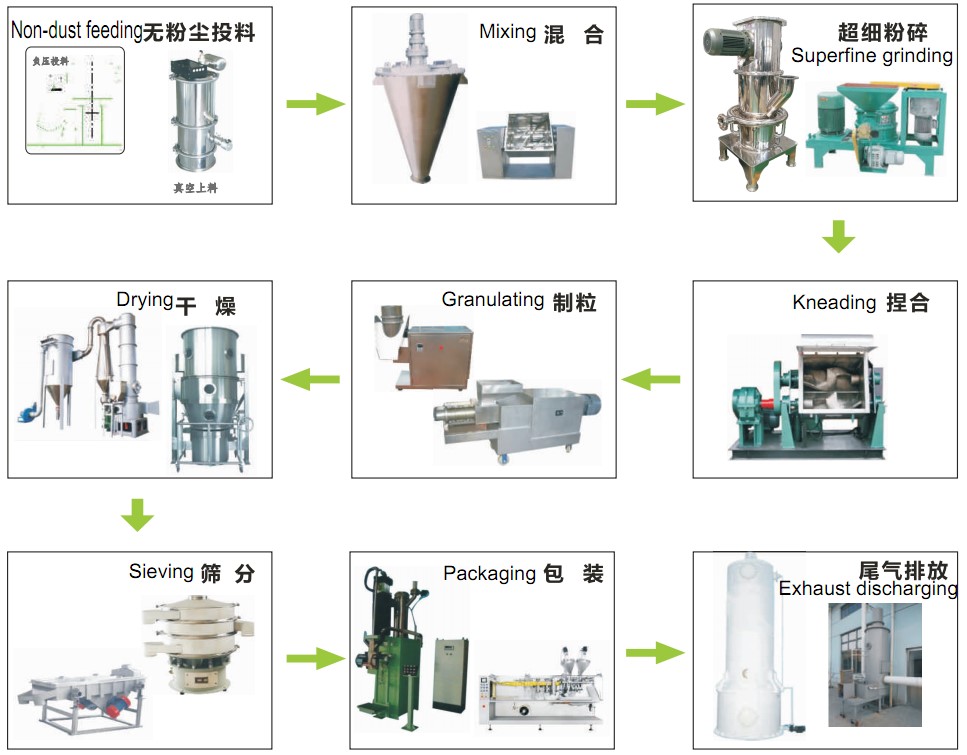

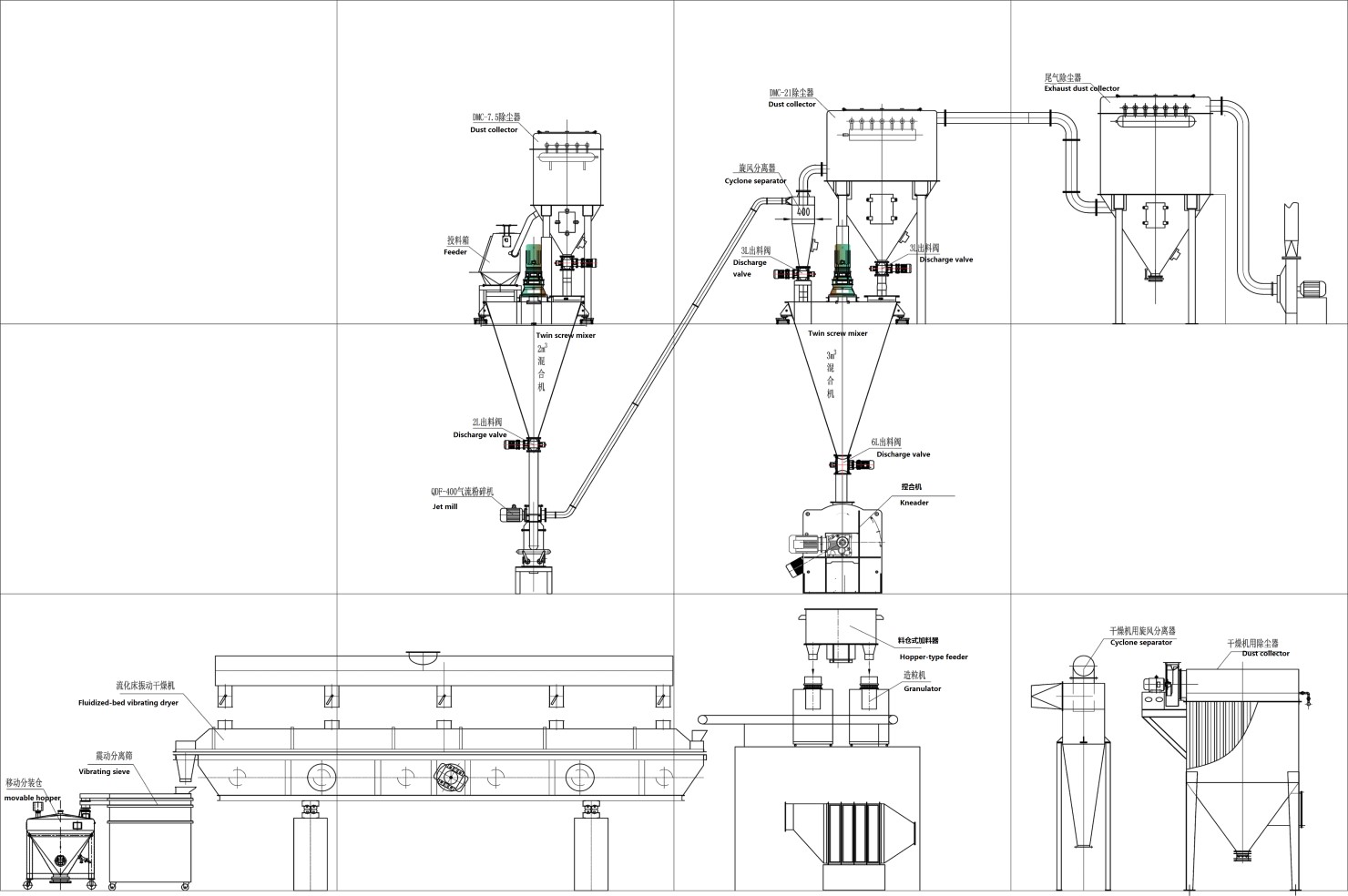

WP chikamu

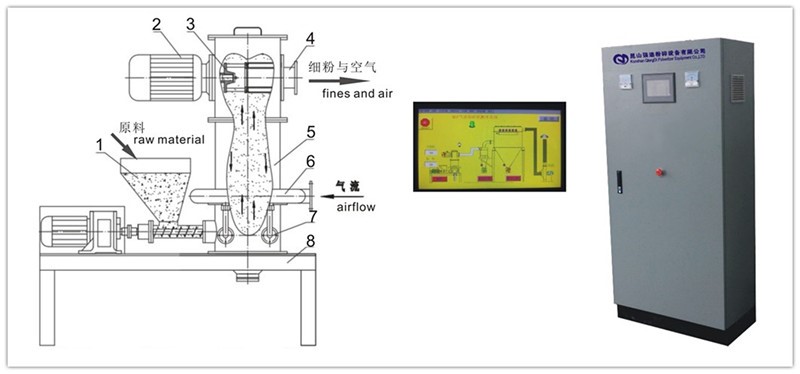

Chekutanga,Raw material feed kubva kune feeder --iyo kuendesa zvinhu kune yekutanga 3 m3musanganisi we premixing, uye muunganidzi weguruva anounganidza guruva panguva yekudyisa, zvino zvakasanganiswa zvinhu zvinopinda muQDF-600 jet chigayo chekugaya, iyo inobuda saizi inogona kugadziriswa nekugadzirisa kwakasiyana kutenderera kumhanya kweiyo classifier vhiri,. Mushure mekugaya, zvinhu zvinoendesa kune dutu uye guruva muunganidzi pamusoro pekutanga 4m3musanganisi kuburikidza necentripetal simba redhizaini fan, wozoendesa kune yechipiri 4m3musanganiswa wekusanganisa pamberi pepakeji kana kuendesa kuWDG system.

WP system musanganiswa wakakwana wejet mill tekinoroji, kusanganisa tekinoroji uye nehungwaru kutonga tekinoroji. inova chigadzirwa chinogutsa chemishonga yezvipembenene kune yakawanda-musanganiswa uye remix,Zvichakadaro, inosangana nechikumbiro chezvakatipoteredza kuti pasava neguruva panguva yese yekuita.

WDG (mvura inorasika granule) inozivikanwawo seyakanyorova poda yakaoma yekumisa mumiriri kana rudzi rwezviyo, iyo mbishi yehupfu inonyorova (WP) inoumbwa negranulation kamwe mumvura, inogona kukurumidza kuparara uye kupararira, granular kugadzirira fomu yakakwirira yakamiswa yakasimba yekuparadzira system.

Granulation ndiyo musimboti wechiitiko chose. Granulator ndiyo kiyi yekuita chokwadi chegranulated mishonga yekuuraya zvipembenene uye yekuomesa maitiro con-figured, iyo yakavakirwa pahunhu hwemishonga yezvipembenene, data yekuyedza uye mienzaniso yekushandisa engineering, kusarudza inotenderera extrusion granulator kana twin screw extruder granulator. maitiro uye extrusion granulation process yakasiyana) .Chinodiwa chekunyorova kwegranulation inenge 8-18%.Zvichienderana nemaitiro echigadzirwa uye maitiro ekugadzira, kuona magadzirirwo ekugadzirisa kunonyanya kusanganisira: kukanda, granulation, kuomesa, kuongorora, kurongedza, mhepo inopisa, hurongwa hwekubvisa guruva.

Chekutanga, iyo mbishi ichatakurwa mu1000L Buffer, wozoti ZGH-1000 vertical mixer muchina neVacuum ZKS-6 yekunyorova musanganiswa wozotakurwa kupinda muXL-450 extrude granulator (3pcs) kuburikidza ne500L mugovani we granule nyoro, wozoenda kuQZL-G000-130. Vibrate Fluid-bed Dryer strip granules then ZS-1800 centrifugal vibration sieve kuti sieve uwane saizi inodiwa granules.

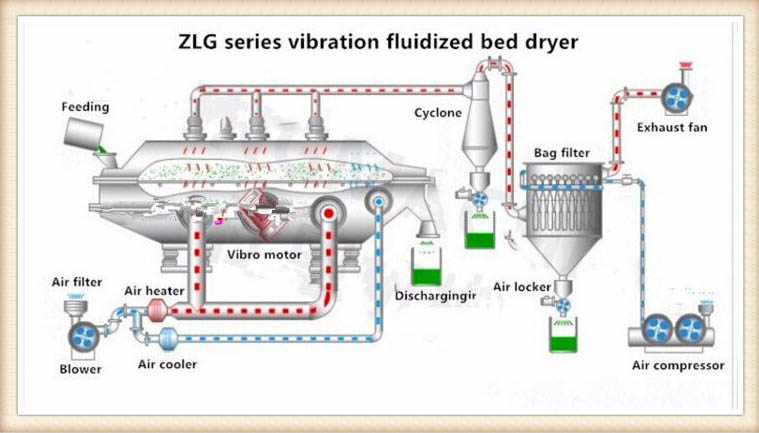

Vibrating fluid bed dryer yechemical powder

Vibrating fluid bed dryer yechemical powder

Kushanda Nheyo

Vibration fluid bed ndiyo tekinoroji nyowani yakagadziridzwa pahwaro hweiyo static fluid bed. Mechanical vibration inowedzerwa pamubhedha wemvura. Zvimedu zvakanyorova zvinopinda mumhepo uye zvinogadzira mubhedha wemvura. Nyaya yacho inodzingwa nekuda kwesimba rinonakidza. Kudengenyeka kwendiro yekugovera mhepo kunokurudzira kuyerera kwezvinhu zvimedu uye kufamba kwezvinhu mumubhedha wemvura. Iyo fluid inobata mhepo inopisa uye panguva imwechete inotakura kupisa uye kutamisa hukuru. Chigadzirwa chakaomeswa chinobudiswa kuburikidza nechiteshi chekubuda.

Hunhu

1. Inoshandisa advanced vibrofluidization tekinoroji, kukuvadzwa kwezvinhu zvakaomeswa particle surface idiki.

2. Kufamba kwakasimba, kugadzikana kwakanaka.

3. Kuzununguka kunokonzera fluidization, kuomeswa kwemhepo kuyerera kwemhepo kunoderedzwa, uye mashoma mashoma anodzidziswa.

4. Nguva yekugara kwezvinhu inowirirana, chigadzirwa chemhando yakaenzana.

5. Inoshandiswa pakuomeswa kwezvinhu zvinopisa kupisa munguva pfupi, senge, pamusoro pemvura

kuomeswa kweCUSO4 · 5H2O ine crystal mvura, MgSO4 · 7H2O.

Applicable scope

Inogona kushandiswa mukuoma kana kutonhora maitiro, anoshanda kune iyo particle yakakura kana zvimedu uye isiri nyore kuyerera kwezvisina kurongeka zvezvigadzirwa, kana nekuti kuita kuti zvimedu zvisanyanya kudikanwa uye kuchengetedza yakazara fluidization velocity yezvigadzirwa uye nyore kusunga, inonzwa nekuoma kwekushisa uye ine zvinhu gesso chigadzirwa pamusoro pemvura kubviswa kubva.

Technical parameter

| Model | Fluidized bed area (M2) | Inlet tembiricha yemhepo (oC) | Outlet air tembiricha (oC) | Evaporation mvura kugona (kg) | Motor | |

| Model | Kw | |||||

| ZLG3×0.30 | 0.9 | 70-140 | 40-70 | 20-35 | ZDS31-6 | 0.8×2 |

| ZLG4.5×0.30 | 1.35 | 70-140 | 40-70 | 35-50 | ZDS31-6 | 0.8×2 |

| ZLG4.5×0.45 | 2.025 | 70-140 | 40-70 | 50-70 | ZDS32-6 | 1.1×2 |

| ZLG4.5×0.60 | 2.7 | 70-140 | 40-70 | 70-90 | ZDS32-6 | 1.1×2 |

| ZLG6×0.45 | 2.7 | 70-140 | 40-70 | 80-100 | ZDS41-6 | 1.5 × 2 |

| ZLG6×0.60 | 3.6 | 70-140 | 40-70 | 100-130 | ZDS41-6 | 1.5 × 2 |

| ZLG6×0.75 | 4.5 | 70-140 | 40-70 | 120-140 | ZDS42-6 | 2.2 × 2 |

| ZLG6×0.9 | 5.4 | 70-140 | 40-70 | 140-170 | ZDS42-6 | 2.2 × 2 |

| ZLG7.5×0.60 | 4.5 | 70-140 | 40-70 | 130-150 | ZDS42-6 | 2.2 × 2 |

| ZLG7.5×0.75 | 5.625 | 70-140 | 40-70 | 150-180 | ZDS51-6 | 3.0 × 2 |

| ZLG7.5×0.9 | 6.75 | 70-140 | 40-70 | 160-210 | ZDS51-6 | 3.0 × 2 |

| ZLG7.5×1.2 | 9 | 70-140 | 40-70 | 200-260 | ZDS51-6 | 3.0 × 2 |

Zvakawanda zvezvikumbiro

Muchina uyu unotora peya imwe inotenderera yekukuya blade kukuya zvinhu zvakanyorova kuita column-shape granule nesimbi isina tsvina sieve silinda iyo inopihwa pelletize mune inotevera process.

Inogona kugadzirisa zvinhu zvakanyorova uye kuwana hukuru hwakasiyana maererano nezvinhu uye zvinodiwa.

ZVINOITA KUSHANDA:

Mota simba rinofambiswa neiyo triangle bhandi-vhiri kubhokisi regiya mune inotambira, uye rinogovaniswa simba nezvikamu zvekutapurirana mubhokisi regiya. Wedzera zvinhu zvakasvibirira muhopi yekudyisa, dzvanya kubva kumusoro.

Mushure mekusanganiswa, zvinhu zvacho zvinoputirwa muchute yekudyisa uye kumanikidzirwa kubuda kunze nebadza rakakosha. Kana zvinhu zvacho zvazara mugomba riri pakati peblade nescreen mesh, banga rekucheka rinoricheka kuita saizi yekubatanidza.

Technical Parameters:

| Outut | 150-250kg/awa (flake chimiro), 50-100kg/awa (granule chimiro) |

| Granule saizi | 0.5-2mm |

| Max pressure | 294Kn(30T) |

| Side seal pressure | 9.8Kn |

| Kudyisa mota | 2.2Kw |

| Granulating Motor | 2.2Kw |

| Kumanikidza mota | 7.5Kw |

| Kudyisa screw speed | 6-33 inogadziriswa |

| Kumanikidza Wheel kumhanya | 4-25 inogadziriswa |

| Dimension yekumanikidza vhiri | 240X100mm |

| Huremu (zvinenge) | 2000Kg |

| Main unit dimension | 1600X1000X2300mm |

| Kudzora kabati dimension | 600X400X1300mm |

Usage

Muchina uyu unonyanya kukodzera indasitiri yemishonga, indasitiri yezvekudya, indasitiri yekunwa zvinwiwa uye zvichingodaro, Inogona kuita yakamutswa mbishi zvinhu qranuate inodiwa qanule. Kunyanya, yakakodzera kune mbishi zvinhu zvine adhesive inonamira.

Features:

Zvese zvikamu zvakabatwa neraw material mumushini uyu zvinogadzirwa nesimbi isina tsvina. Kuonekwa kwayo kunaka. Kubuda kwaro kuri otomatiki.Saka inogona kudzivirira mamiriro akakuvadzwa akakonzeresa manual. Inokodzera-inokwanisa mukugadzirwa kwemutsara zvakare.

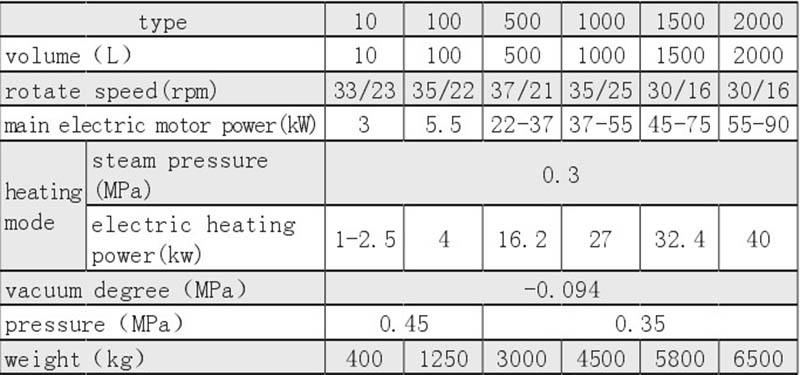

Main technical patameters

| Saizi yebanga rekugaya (mm) | 300 | 400 |

| Diameter ye granule (mm) | Φ2~2.2(Inogona kunge inoenderana nezvinodiwa nevatengi) | Φ1.2~3(Inogona kunge inoenderana nezvinodiwa nevatengi) |

| Zvose zviyero(mm) | 700×540×1300 | 880×640×1300 |

| Simba remota (kw) | 3 | 4 |

| Huremu(kg) | 350 | 400 |

| Kukwanisa kugadzira (kg/h) | 100-200 | 140~400 |

Principle

LGH vertical type musanganisi inogadzirwa nepasi kutumira zvinhu zvikwasvi uye nekumhanya kukuru kupwanya matanda, Iwo epazasi magwairi anoenderera mberi achitumira zvinhu kumusoro pamwe nemadziro emudziyo.

Kumhanya kwekupwanya maoars anopwanya zvinhu zvachose kuita kutenderera kwezvinhu kunge vortex, kupedzisa kusanganiswa kwakafanana munguva pfupi.

Zvimiro zvemidziyo

LGH vertical type yakakwira yekumhanyisa kusanganisa muchina ndiyo nyowani mhando yepamusoro-inoshanda musanganisi wefekitori yedu, iyo yakaunganidza hunyanzvi hwepamusoro hwepamba nemhiri kwemakungwa.

1.Iyo pasi zvinhu oars zvinoramba zvichitumira zvinhu kumusoro kuburikidza ne centrifugal force. Uye iyo yepamusoro zvinhu inodonhedza pasi pakati, kugadzira iyo zvinhu kutenderera kunge vortex.

2.High-speed crushing oars inoputsa zvinhu zvakawanda zvakakwana izvo zvinotumira nepasi pasi.

3.Nyaya yacho inogona kusanganisa zvakafanana munguva pfupi nekuda kwemakumbo maviri akakwirira-speed revolution. Iko kusanganisa kumhanya uye kufanana ndiyo yakanakisa mumhando dzese dzemuchina wekusanganisa mumusika wepamba. Iyo yakafanana ndeye 100% musanganiswa.

4.Kutanga kuvhara kwevhavha, kubudisa kukurumidza kunokurumidza, uye muchina uri nyore kuchenesa.

5.Muchina wekubatanidza zvikamu zvakagadzirwa nesimbi isina tsvina, panguva yekusanganiswa, zvinhu hazvizogadziriswi, metamorphic uye kurasikirwa.

6.Muchina unokodzera zvakasiyana-siyana zvakaoma uye zvakanyorova zvinhu kusanganisa, kunyanya masutu ekusanganiswa kwehuku essence, mushonga wakanyungudutswa, chinwiwa chakanyungudutswa nezvimwe zvakadaro.

Iyo inonziwo rotary vibro sifter,vibratory sieve.Inogona kusefa mvura semvura yakaraswa nemafuta anorasa nezvimwewo,kubvisa kusachena kuri muzvinhu,zvakadai sehupfu hwemukaka,mupunga,chibage etc.Classify/grade the mix powder into different size yaunoda.

Tsanangudzo

Rotary charcoal/coal ultrasonic vibrating screen sifter machine yakagamuchirwa hunyanzvi hwepamusoro hwepamusoro hwekuongorora michina. Iyo ine ultrasonic mugadziri uye vibrating skrini. Kubudirira kwakakosha mukuongorora kunyatsoshanda. Iyi sieving muchina unotora advanced intelligent vibrating ultrasonic controller uye yakagadzirisa matambudziko mazhinji anokonzerwa nekamwe frequency, kunyatsoona musanganiswa unonzwisisika we ultrasonic function uye vibration sieve.

Multifunctions sezvinotevera:

1. Kuronga

Iyo yakawanda-layer mhando inogona kuvheneka uye kuparadzanisa mapoka mashanu ezvimedu zvakasiyana panguva imwe chete. Inokodzera zvinhu zvakaoma.

2. Kusefa

Musanganiswa wekusimba uye wemvura unogona kupatsanurwa zvinobudirira nemhando imwe chete kana yakawanda-yakapetwa mumhando dzakasiyana dzegiredhi.

3. Bvisa tsvina

Iyo unit inogona kukurumidza kupatsanura mashoma oversize kana undersize zvimedu kubva muhuwandu hwezvinhu

Yekuchenesa sisitimu tinoshandisa ultrasonice mudziyo weRotary marasha/marasha eultrasonic vibrating screen sifter muchina.

Spare parts

Kneader chishandiso chakanakira kukanya, musanganiswa we polymerize zvinhu zvine high viscosity uye elasto plastiki. Imwe neimwe seti yekneader ine zvidimbu zviviri zve sigma blades mukati me w type yekusanganisa kamuri. Inoshandiswa zvakanyanya kukanya, kusanganisa, kupwanya, kuparadzira uye kuitazve polymerize yakakwira viscosity paste kana elastoplastic zvinhu, izvo zvisingakwanisi kugadziridzwa neyakajairwa poda musanganiswa uye mvura inosanganisa. Inogona kushandiswa mumaindasitiri anodiwa kune yakakwira density kukanya senge agrichemical, makemikari, rabha, chikafu uye kugadzirira mishonga. Mhedzisiro yacho iri nani pane musanganisi. Kneader chinhu chakakosha kusanganisa midziyo ine mashizha maviri. Inokurumidza imwe inowanzotenderera ichimhanya 42 paminiti, inononoka imwe ichimhanya 28 revolutions paminiti. Kumhanya kwakasiyana kunoita kuti kusanganisa zvinhu zviwane homogenate nekukurumidza.

Plant Engineering

- Plant design

- Maitiro ekutarisa, kutonga uye otomatiki

-Kuvandudzwa kweSoftware uye chaiyo nguva yekushandisa hurongwa

- Injiniya

- Michina kugadzira

Project Management

- Kuronga kweprojekiti

-Kutarisira nzvimbo yekuvaka uye manejimendi

-Kuiswa uye kuyedzwa kwezviridzwa uye kutonga masisitimu

- Machina uye chirimwa kutumwa

- Kudzidziswa kwevashandi

- Tsigiro mukati mekugadzira

Project Definition

- Kugoneka uye pfungwa kudzidza

- Mutengo uye Profitability kuverenga

-Timecale uye kuronga zviwanikwa

- Turnkey mhinduro, kukwidziridzwa kwechirimwa uye zvemazuva ano mhinduro

Project Design

- Vanoziva mainjiniya

-Kushandisa yazvino matekinoroji

-Kushandisa ruzivo rwakawanikwa kubva kumazana ezvishandiso pane chero maindasitiri

-Kuwedzera hunyanzvi kubva kune edu ane ruzivo mainjiniya uye vatinoshanda navo