Indasitiri yebhatiri uye Mamwe Kemikari Material Kushandisa Fluidized-bed Jet Mill

Fluidized bed pneumatic mill ndiyo midziyo inoshandiswa kupwanya zvinhu zvakawoma kuita superfine poda, iine chimiro chakakosha seizvi:

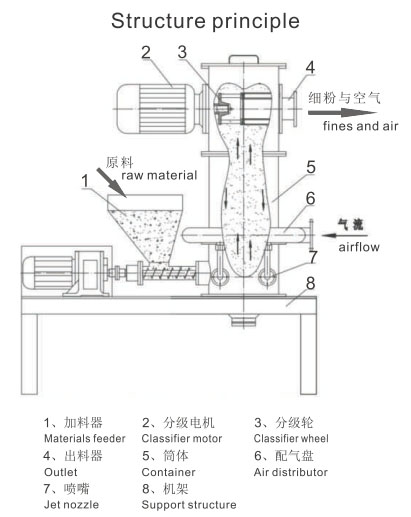

The Product is a fluidized bed pulverizer ine compression air as the crushing medium. Muviri weguyo wakakamurwa kuita zvikamu zvitatu, zvinoti nzvimbo yekupwanya, nzvimbo yekutapurirana uye nzvimbo yekugidha. Iyo Grading Area inopihwa negiredhi vhiri, uye kumhanya kunogona kugadziriswa neinoshandura. Imba yekupwanya inoumbwa nekupwanya nozzle, feeder, etc. Iyo ring sir supply disc kunze kwekupwanya kanister yakabatana neinopwanya muromo.

Izvo zvinhu zvinopinda mukamuri rekupwanya kuburikidza nemushonga wezvinhu. Mhepo yekutsikirira inopinza mukamuri yekupwanya ichimhanya zvakanyanya kuburikidza nemapfumo mana ekupwanya akashongedzerwa. Izvo zvinhu zvinowana kukurumidza muiyo ultrasonic jetting kuyerera uye kudzokorodza kukanganisa uye kudhumhana panzvimbo yepakati yekuchinjisa yekamuri yekupwanya kusvika yapwanyika. Iyo yakapwanyika zvinhu inopinda mukamuri yegiredhi nekukwira. Nekuti mavhiri egiredhi anotenderera nekumhanya kukuru, kana zvinhu zvichikwira, zvimedu zviri pasi pesimba recentrifugal rakagadzirwa kubva kumagiredhi rotor pamwe nepakati pesimba rakagadzirwa kubva kuviscosity yemhepo inoyerera. Kana zvimedu zviri pasi pesimba recentrifugal rakakura kupfuura simba recentripetal, zvimedu zvakakoshwa zvine dhayamita hombe kupfuura zvidimbu zvinodikanwa hazvipindi mukamuri yemukati yevhiri regiredhi uye zvinodzokera mukamuri yekupwanya kuti inopwanywa. Iwo matutu akanaka anoteerana nedhayamita yezvimedu zvegiredhi zvinopinda muvhiri regiredhi uye kuyerera mumhepo inoparadzanisa nechamupupuri chemukati mevhiri regiredhi nekuyerera kwemhepo uye inounganidzwa nemuunganidzi. Mhepo yakasefa inoburitswa kubva kumhepo intaker mushure mekugadziriswa kwebhegi resefa.

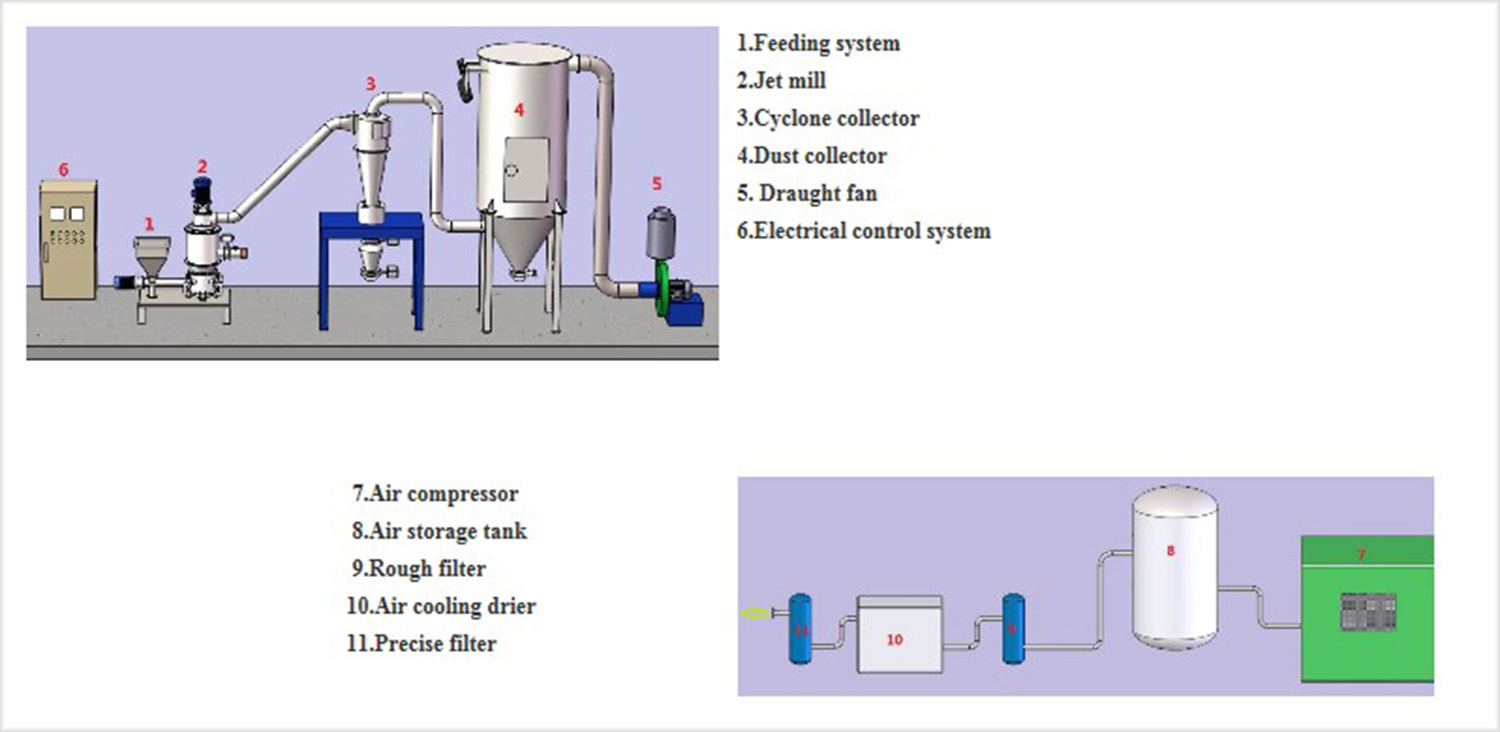

Iyo pneumatic pulverizer inoumbwa nemhepo compressor, mafuta remorer, gasi tangi, chando dryer, mhepo sefa, fluidized mubhedha pneumatic pulverizer, cyclone separator, muunganidzi, air intaker nevamwe.

Detail show

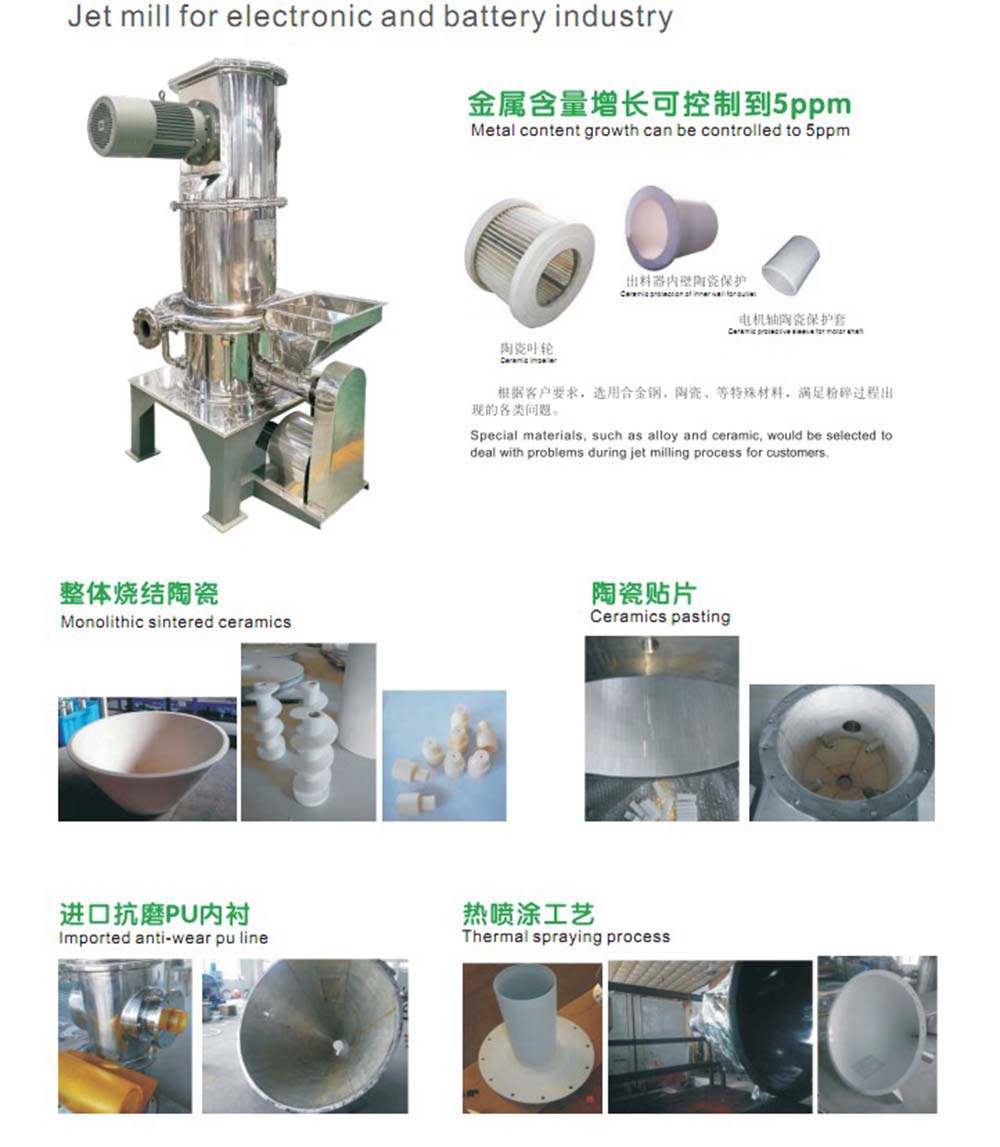

Ceramics inonamira uye PU lining muzvikamu zvese zvekukuya zvinosangana nezvigadzirwa kudzivirira zvimedu zvesimbi zvinotora zvinotungamira kune kusashanda mhedzisiro yezvigadzirwa zvekupedzisira.

1.Precision ceramic coatings, 100% inobvisa kusvibiswa kwesimbi kubva mukugadzirisa zvinhu zvekugadzirisa kuvimbisa kuchena kwezvigadzirwa. Kunyanya yakakodzera kune simbi inodiwa yezvigadzirwa zvemagetsi, senge cobalt yakakwira acid, lithium manganese acid, lithium iron phosphate, Ternary Material, lithium carbonate uye Acid lithium nickel uye cobalt etc bhatiri cathode zvinhu.

2. Hapana kukwira kwekushisa: Tembiricha haizowedzeri sezvo zvinhu zviri kuputswa pasi pemamiriro ekushanda ekuwedzera kwepneumatic uye tembiricha iri mumilling cavity inochengetwa yakajairika.

3.Endurance: Inoshandiswa kune zvinhu zvine Mohs Kuoma pasi peGiredhi 9. sezvo kugadzirwa kwekugaya kunongobatanidza kukanganisa uye kudhumhana pakati pezviyo pane kudhumhana nemadziro.

4.Energy-inoshanda: Kuchengetedza 30% -40% kana ichienzaniswa nemamwe air pneumatic pulverizers.

5.Iinert gasi inogona kushandiswa semidhiya yekugaya zvinopfuta uye zvinoputika zvinhu.

6. Iyo yose system inopwanyika, guruva rakaderera, ruzha rwakaderera, nzira yekugadzira yakachena uye kuchengetedzwa kwezvakatipoteredza.

7. Iyo sisitimu inotora yakangwara touch screen control, nyore kushanda uye kutonga kwakaringana.

8.Compact structure: kamuri yemuchina mukuru inoumba inovhara redunhu rekupwanya.

Iyo inoyerera chati ndeye yakajairwa kugaya kugadzirisa, uye inogona kugadziridzwa kune vatengi.

| model | QDF-120 | QDF-200 | QDF-300 | QDF-400 | QDF-600 | QDF-800 |

| Working pressure (Mpa) | 0.75~0.85 | 0.75~0.85 | 0.75~0.85 | 0.75~0.85 | 0.75~0.85 | 0.75~0.85 |

| Kushandiswa kwemhepo (m3/min) | 2 | 3 | 6 | 10 | 20 | 40 |

| Diameter yezvinhu zvakadyiswa (mesh) | 100~325 | 100~325 | 100~325 | 100~325 | 100~325 | 100~325 |

| Kunaka kwekupwanya (d97μm) | 0.5~80 | 0.5~80 | 0.5~80 | 0.5~80 | 0.5~80 | 0.5~80 |

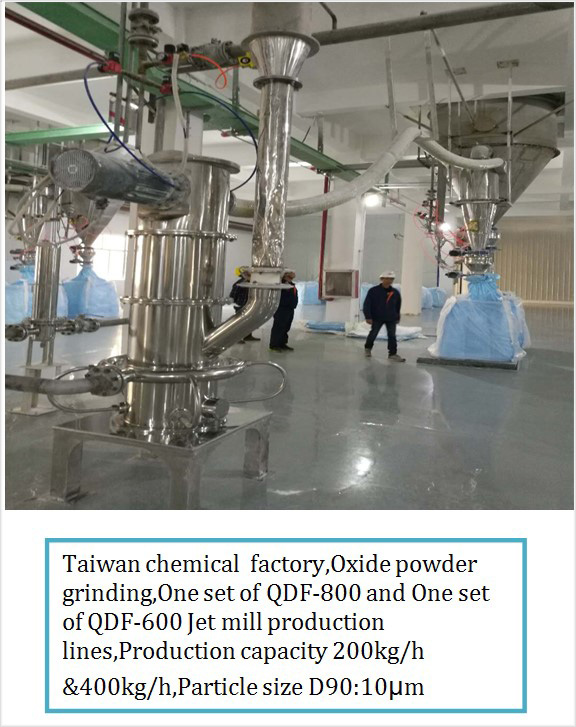

| Kugona (kg/h) | 0.5~15 | 10~120 | 50~260 | 80~450 | 200~600 | 400 ~ 1500 |

| Simba rakaiswa (kw) | 20 | 40 | 57 | 88 | 176 | 349 |

| Material | Type | Diameter yezvikamu zvakadyiswa | Diameter yezvikamu zvakasunungurwa | Output(kg/h) | Kushandiswa kwemhepo (m3/min) |

| Cerium oxide | QDF300 | 400(Mesh) | d97,4.69μm | 30 | 6 |

| Flame retardant | QDF300 | 400(Mesh) | d97,8.04μm | 10 | 6 |

| Chromium | QDF300 | 150(Mesh) | d97,4.50μm | 25 | 6 |

| Phrophyllite | QDF300 | 150(Mesh) | d97,7.30μm | 80 | 6 |

| Spinel | QDF300 | 300(Mesh) | d97,4.78μm | 25 | 6 |

| Talcum | QDF400 | 325(Mesh) | d97,10μm | 180 | 10 |

| Talcum | QDF600 | 325(Mesh) | d97,10μm | 500 | 20 |

| Talcum | QDF800 | 325(Mesh) | d97,10μm | 1200 | 40 |

| Talcum | QDF800 | 325(Mesh) | d97,4.8μm | 260 | 40 |

| Calcium | QDF400 | 325(Mesh) | d50,2.50μm | 116 | 10 |

| Calcium | QDF600 | 325(Mesh) | d50,2.50μm | 260 | 20 |

| Magnesium | QDF400 | 325(Mesh) | d50,2.04μm | 160 | 10 |

| Alumina | QDF400 | 150(Mesh) | d97,2.07μm | 30 | 10 |

| Pearl simba | QDF400 | 300(Mesh) | d97,6.10μm | 145 | 10 |

| Quartz | QDF400 | 200(Mesh) | d50,3.19μm | 60 | 10 |

| Barite | QDF400 | 325(Mesh) | d50,1.45μm | 180 | 10 |

| Foaming agent | QDF400 | d50,11.52μm | d50,1.70μm | 61 | 10 |

| Ivhu kaolin | QDF600 | 400(Mesh) | d50,2.02μm | 135 | 20 |

| Lithium | QDF400 | 200(Mesh) | d50,1.30μm | 60 | 10 |

| Kirara | QDF600 | 400(Mesh) | d50,3.34μm | 180 | 20 |

| PBDE | QDF400 | 325(Mesh) | d97,3.50μm | 150 | 10 |

| AGR | QDF400 | 500(Mesh) | d97,3.65μm | 250 | 10 |

| Graphite | QDF600 | d50,3.87μm | d50,1.19μm | 700 | 20 |

| Graphite | QDF600 | d50,3.87μm | d50,1.00μm | 390 | 20 |

| Graphite | QDF600 | d50,3.87μm | d50,0.79μm | 290 | 20 |

| Graphite | QDF600 | d50,3.87μm | d50,0.66μm | 90 | 20 |

| Concave-convex | QDF800 | 300(Mesh) | d97,10μm | 1000 | 40 |

| Black silicon | QDF800 | 60(Mesh) | 400(Mesh) | 1000 | 40 |